Supplier Sustainable Development

15 minTo further develop partnerships in the supply chain based on responsible business behavior, we are engaging our suppliers and trading partners in our endeavor to foster sustainable development.

Our approach

We believe sustainable supply chains ensure the well-being of the people and environments they procure from, as we seek to grow our business through ethical and legal business practices. We are therefore committed to leveraging our purchasing power to benefit those partners whose values align most closely with ours. Furthermore, the rise of supply chain transparency legislation points to the increasing mandate that a company must be aware of the economic, environmental, and social dimensions of its supply chain, and that it must proactively monitor and manage those dimensions.

The dormakaba Supplier Code of Conduct (SCoC) outlines our requirements with regard to human rights, fair working conditions, environmental responsibility, and business ethics, among others. It is integrated into our online bidding system and is also part of our standard supplier contracts.

Download the dormakaba Supplier Code of Conduct

DownloadOur activities

Our global supply chain is large and complex, which poses a challenge in this regard. Global procurement volumes with external vendors, excluding inventory, correspond to approximately 32% of total sales, making the company’s procurement strategy highly relevant to achieving our financial and sustainability targets. The number of active suppliers for goods and services is approximately 21,000, with spend focused in Europe (45.7%), North America (27.4%), and Asia (22.6%).

Supplier Sustainable Development is one of the strategic topics in our Sustainability Framework 2021–2027, for which we have set ambitious targets. By 2027, we aim to:

- assess all high-risk suppliers for their sustainability management by a third party or off-board them for lack of participation

- have at least 45% of our high-risk suppliers participate in our sustainability engagement program

- close at least 80% of high-priority corrective actions by assessed suppliers

- have 90% of assessed suppliers with priority findings complete a sustainability training

- provide information regarding conflict minerals for high-risk suppliers.

To ensure our suppliers contribute to social and environmental well-being, dormakaba focuses on five areas:

- Identifying supply chain risks

- Supplier off-site assessments

- Supplier on-site audits

- Training of internal and external stakeholders

- Procedures in case of non-participation or non-compliance

Identifying supply chain risks

dormakaba has defined a target group for sustainability assessments based on identified sustainability risk factors – such as origin country and the material content of the goods procured. The latter refers to material compliance topics that are included in the European Union’s REACH regulations and RoHS Directive. Suppliers over a certain procurement threshold were taken into consideration as part of the categorization work.

To determine sustainability risk factors on a country level, an impact assessment and hotspot analysis were used as a baseline. The hotspot analysis identified the following sustainability topics as being of highest relevance in the supply chain: (1) Energy and Emissions; (2) Effluents and Waste; (3) Occupational Health and Safety; (4) Materials; (5) Training and Education; (6) Freedom of Association; (7) Human Rights. For these high-impact topics, any supplier from countries listed as high-risk was included in the sustainability target group for assessment. The high-risk group includes approximately 10% (2,089) of our Tier 1 supplier base, both for direct (e.g. material goods) and indirect (e.g. services) spend.

Supplier categorization for sustainability assessment

Supplier off-site assessments

Since 2019, we have been working together with EcoVadis, a leading provider for monitoring sustainability in global supply chains, to reduce supplier risk and support supplier development. The assessment covers 21 sustainability criteria across four areas (environment, labor and human rights, ethics, sustainable procurement).

We apply a comprehensive self-assessment for all potential new suppliers as part of the supplier qualification process. The self-assessment questions related to sustainability are regularly assessed and improved based on changes to our sustainability strategy and regulatory trends.

We invited over 400 high-risk suppliers from our Tier 1 group to participate in the EcoVadis assessment in FY 2021/22.

In FY 2021/22, we engaged over 400 high-risk suppliers and asked them to participate in the EcoVadis assessment. The positive participation rate was 28%. Of the 117 suppliers with a completed rating as at 30 June 2022, 33% achieved a bronze, silver, gold, or platinum rating by EcoVadis, considered as moderate or advanced performance. However, the majority of assessed suppliers (54%) had only partial performance, with an additional 14% considered to have insufficient performance.

Since the launch of our collaboration with EcoVadis, 18.7% of our high-risk suppliers have been assessed. Improvement plans for 234 suppliers were requested because of the assessment results and 52% of these were closed during this reporting year. Furthermore, six business relationships were terminated and two suppliers were blocked from new business.

Overall score distribution *

*All EcoVadis-rated dormakaba suppliers since 2019

Supplier on-site audits

To examine our suppliers’ situation on-site, we developed a standard audit questionnaire that contains topics related to quality management. Among these, sustainability topics such as internal Code of Conducts (CoCs), the dormakaba SCoC, and labor, health and safety, and environmental standards are checked. Auditors are asked to check documentation on-site related to:

- Workers’ ages and identity records

- Receipt of wages

- Training and communication on internal CoCs

- Signature of the dormakaba SCoC

- Hazardous materials storage and worker training on safe handling

- Injury rates

- Development of water, energy, and waste metrics over recent years.

As on-site audits require immense effort and cost, we have introduced a risk assessment process that takes into account the potential risk of specific locations, products, and performance. This risk assessment results in a score ranking, indicating the frequency of auditing required for the relevant supplier.

In FY 2021/22, we conducted on-site audits for 24 suppliers in China. Regarding sustainability criteria, there were no findings of non-conformance. In addition, we have reassessed the audit criteria and now include mandatory on-site quality audits based on countries of high-risk for forced labor and for high-risk outsourced services. The Supplier Audit Checklist has also been updated with a more comprehensive sustainability and compliance section.

Procedures in case of non-participation or non-compliance

We have procedures and process flows in place for auditing rules and corrective action plans in terms of the sustainability performance of suppliers. Since FY 2020/21, we have been integrating a sustainable development clause into contracts for new suppliers and for existing suppliers in the course of contract renewals. The so-called Sustainability Supplementary Agreement establishes and describes the suppliers’ obligation to participate in and pay for off-site assessments and/or on-site audits, and to commit to and implement an improvement plan if performance is below our defined benchmarks.

In addition, at the beginning of the supplier relationship, the supplier is presented with the dormakaba SCoC for signature. Suppliers refusing to sign the SCoC or who do not have their own of equal quality are blocked.

If a supplier is invited to participate in the EcoVadis off-site assessment, further actions are determined by their assessment score. For suppliers with bronze, silver, gold, or platinum level, further reassessments are required in three to five years. For suppliers with partial performance, an annual reassessment is required, and an improvement plan is defined within the EcoVadis system.

Refusal to participate in an off-site assessment qualifies a supplier for an on-site audit. Likewise, suppliers whose off-site assessment score is insufficient are shortlisted for an on-site audit. A corrective action plan is defined in the course of the on-site audit, with a one-year implementation deadline. Suppliers are blocked or placed in active elimination for lack of implementation.

Additionally, a Responsible Procurement Steering Committee meets regularly to take decisions on a case-by-case basis for special circumstances, such as when dealing with monopoly suppliers, quality checks of suppliers’ internal Code of Conducts, acceptance of sustainability assessments by providers other than EcoVadis, and monitoring and evaluation of suppliers listed as blocked or in active elimination due to sustainability performance.

Sustainability trainings for procurement employees

Our procurement employees have a core role in achieving our goals related to Supplier Sustainable Development. Their understanding of the sustainability aspect and the program with EcoVadis is key. Therefore, employees who are working together with suppliers, participate in training programs that prepare them for sustainability- and assessment-related conversations with the partners. In total, 34 colleagues were trained and 18 attended the virtual supplier onboarding meetings in FY 2021/22.

Further activities

In FY 2021/22, we continued to make significant progress in our supplier sustainability engagement strategy, for example by initiating virtual supplier onboarding meetings to improve the response rate in the EcoVadis Assessment Program. Furthermore, we have started working on the implementation of SAP Ariba, to automize processes for supplier onboarding, development, and communication. Through this system, we will be able to collect and evaluate sustainability-related information of all suppliers. In case of ESG-related risks, we contact the suppliers to participate in our sustainability assessment and improvement process (in partnership with EcoVadis). This applies to all suppliers from high-risk countries and those that provide high-risk commodities, before registering on the platform. Furthermore, a more detailed sustainability questionnaire will be sent out to specific suppliers, for example regarding recycled content, conflict minerals, and various certifications. The platform will be launched at the end of 2022.

Lastly, we developed a Sustainable Procurement Directive that is currently under review for approval and will come into force in FY 2022/23. The policy includes basic regulations on contractual sustainability agreements, sustainable purchasing factors and criteria, requests for sustainability information, life cycle costing, supplier categorization for sustainability assessments, and procedures in case of non-participation or non-compliance.

Improving transparency regarding conflict minerals in the supply chain

In FY 2020/21, we joined the Responsible Minerals Initiative, a well-respected multi-stakeholder organization evolving business practices to support responsible mineral production and sourcing globally, including but not limited to conflict-affected and high-risk areas. The information and tools we can access through the organization help us to improve transparency in our supply chain with regard to the use of materials, including conflict minerals.

Using their Conflict Minerals Reporting Template, we launched a US-wide campaign with more than 1,200 suppliers (excluding non-production suppliers and services) to provide relevant information to our customers to whom the aforementioned law might apply. As at 30 June 2022, around 60% of the contacted suppliers submitted Conflict Mineral Statements. Approximately 40% of the supplier responses indicated that no 3TGs (Tungsten, Tantalum, Tin, and Gold) were intentionally used in the delivered goods, 13% have a strong compliance program, and 6.6% have weak conflict mineral procedures.

In this financial year, more than 700 suppliers globally provided Conflict Minerals Reports upon our request.

Outlook

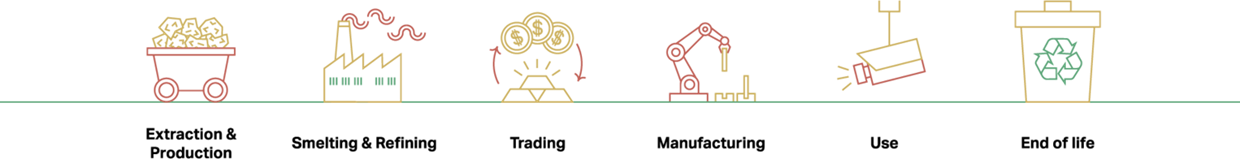

During the next financial year, we will focus on developing processes that contribute to our target of improving the percentage of recycled content in our metal products. With regard to conflict minerals and supply chain transparency, we plan to establish a Conflict Minerals Directive based on the OECD Due Diligence Framework.

And of course, we will continue to assess suppliers for their sustainability management through EcoVadis. We acknowledge that following up with suppliers, encouraging their participation in the assessment, and monitoring progress on corrective actions requires time and resources. This has proved a challenge in FY 2020/21. Therefore, we will also increase capacity internally by recruiting additional dedicated staff for supplier sustainability assessments for each business region. We strongly believe this increased focus will provide our business partners with better support and awareness and will result in better participation and improvement rates.