Outro

About this report

This is the dormakaba Holding AG (“dormakaba”) Sustainability Report 2023/24, which highlights our sustainability commitments, strategic approach, and progress, and is geared towards all stakeholders. This is the company’s ninth sustainability report. This report has been prepared in accordance with the GRI Standards. The report covers the financial year 2023/24, from 1 July 2023 to 30 June 2024, and it was published on 3 September 2024. dormakaba reports on an annual cycle and published the previous report in August 2023.

The compensation of the Board of Directors and the Executive Committee, as well as the financial statements found in the Annual Report, were audited by an external auditor. Select KPIs from the Sustainability Report have also been assured.

Due to improved data analysis and calculation procedures, we have better granularity on our Scope 3 emissions figures. We are better able to differentiate between different categories, leading to a restatement of Scope 3 Category 1: Purchased goods and services, as some emissions attributed to this category are now reflected under categories 2, 4, 5, 6, or 9. The restated figures are available in our ESG Performance table.

Significant changes to the organization and its supply chain

The Board of Directors of dormakaba appointed Till Reuter as the new CEO effective 1 January 2024. Till Reuter has the broad industrial expertise and proven leadership skills to further develop dormakaba on its growth path and effectively execute its strategy and transformation program. He stepped down from the Board of Directors of dormakaba at the same time, having been a member since October 2023.

Alex Housten, Chief Operations Officer (COO) and member of the Executive Committee (EC), left the company at the end of March 2024. The Board of Directors has appointed Carsten Franke to take over the role effective 1 August 2024. He possesses an extensive track record in driving companies toward operational excellence through optimizing their manufacturing footprint and supply chain, as well as enhancing plant and procurement performance.

Reporting coverage and processes

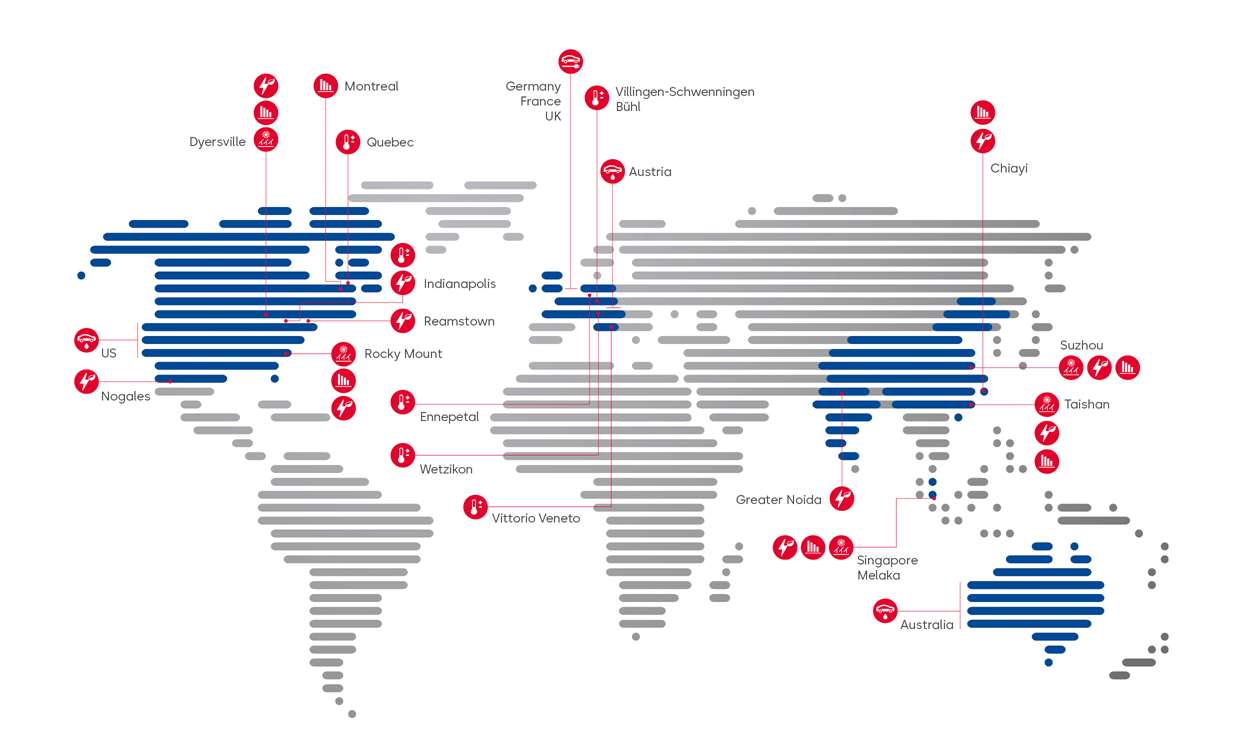

The data presented covers 95% of dormakaba employees in 111 locations worldwide, as represented by the blue dots on the map below. These are locations with more than 20 employees and include all manufacturing facilities. Environmental data, including that on energy, water, waste, and materials consumption, is collected via an internal business intelligence reporting platform. Each location has a dedicated reporter. For everything except materials use, internal reporting deadlines are set for the 6th, 10th, and 12th month of the financial year. Materials use is reported at the end of the financial year. Human Resources data pertaining to GRI 100, such as fluctuation and workforce composition, is gathered through the Group-wide human resources information platform SAP SuccessFactors. Figures on corruption cases, collective bargaining, and working and training hours are gathered on an annual basis by HR for all reporting units in scope via an internal business intelligence reporting platform. Injury rates, injury and accident types, corrective actions, and root cause analysis data is collected in a web-based health and safety tool. Data quality controls and consolidation for all data are provided after the end of the financial year by an external consultant.

The Sustainability Report review process has several phases, including the review of the dedicated chapters (both qualitative and quantitative content) and relevant parts of the ESG Performance table and the Strategic Targets table by topic owners in the Executive Committee and direct reports of the CEO. Furthermore, the CFO and the CEO review abstracts of the chapters, the TCFD report, the ESG Performance table, and the Strategic Targets table. The Audit Committee is responsible for contributing to the integrity of the Sustainability Report and monitoring the assurance of it, and the Board of Directors reviews and approves it.

Sites covered

Transparency and compliance

We are committed to being a socially responsible corporate citizen and to upholding the principles of international conventions and laws and internal rules and regulations. We also expect our suppliers and business partners to adhere to similar standards and rules. We emphasize integrity, governance, and responsible business practices, and regard fair competition as the soundest basis for our growth and corporate success. As a member of the UN Global Compact, we are committed not only to avoiding bribery, extortion, and other forms of corruption, but also to developing related policies and specific programs, both internally and within our supply chain.

We set a clear tone from the top regarding compliance by providing guiding documents and training to all employees. Principles of antitrust regulations, anti-corruption, and ethical business dealings, for example, are part of our Code of Conduct (CoC). The dormakaba CoC is binding for all our employees. It is each employee’s responsibility to comply with laws and internal regulations as per the CoC. The respective manager is responsible for ensuring that employees are familiar with the regulations and understand expectations. In the course of the recruitment and onboarding process, new employees receive and acknowledge the dormakaba CoC. Global Compliance publishes new directives and supports internal communication of any related publications and topics. Functional owners of the directives must ensure appropriate communication and training for the respective addressees. The Group Anti-Corruption and Bribery Directive and the Group Antitrust Directive provide guidance for our employees to ensure compliance with relevant laws and to minimize any related risks.

Specifically, the Group Anti-Corruption and Bribery Directive defines clear requirements in terms of documentation and approval for granting and accepting benefits in the public and private sectors depending on certain thresholds and the mandatory consideration of additional principles to prevent even the mere appearance of corruption. Employees affected, e.g., in sales or procurement, receive training on these requirements. To simplify compliance with the documentation and approval requirements, we have established an electronic workflow. Other anti-corruption measures include – among others – the Global Compliance department providing anti-corruption advice and communication measures, e.g., regarding business benefits before Christmas. Furthermore, employees that are part of our international Compliance Organization are specially trained in anti-corruption and serve as a regional or local contact for related questions. Finally, donation and sponsoring activities are monitored annually to avoid the circumvention of our anti-corruption provisions.

Reporting misconduct and grievances

The CoC outlines the standard procedure for reporting grievances and/or breaches of law. The dormakaba whistleblowing tool is available globally 24/7 and is offered in nine languages. Whistleblowers using the online tool receive a first response within two to three days and are provided with regular updates on their case, if a mailbox allowing anonymous communication has been set up. We strive to create a culture in which employees speak up and are encouraged to address concerns as outlined in the abovementioned process.

Global Compliance carefully considers all notifications received and, depending on the nature of the matter, creates an action plan or sets up a project to solve any potential issues. Remediation progress is tracked by Global Compliance and may include direct legal advice, the involvement of external experts, internal investigations, or the development of workshops or customized training. If necessary, Global Legal and Global Compliance will involve the CEO and/or other relevant members of the Executive Committee. Furthermore, Global Compliance regularly reports on compliance cases on an aggregated level to the Executive Committee.

Information security

Safeguarding our customers’ rights to data protection and privacy includes obtaining data by lawful and fair means, protecting the personal data of customers by adequate information security safeguards, and using customer data responsibly. We have an Information Security Management System (ISMS) in place, which is based on the ISO/IEC 27001:2022 standard. The scope of the certification covers Global IT and digital-based product development in Europe and North America. The Group Information Security Directives and the Data Protection Management System Directive provide guidance for our employees to ensure compliance with relevant laws and to minimize any related risks.

Materiality process in detail

In FY 20/21, dormakaba carried out a comprehensive materiality reassessment as part of the development of a new sustainability strategy for 2021–2027. We assess any emerging global issues or risks for future consideration on an annual basis.

Impact assessment

As part of the materiality process, we focused our efforts on a study-based impact assessment of sustainability topics along our value chain. The aim was to focus efforts where dormakaba can have the most impact on sustainable development. The analysis included dormakaba data from procurement, sales, production, and human resources. This was overlaid with over 50 risk indicators from social hotspot databases, the World Bank, and the Organisation for Economic Co-operation and Development (OECD).

The approach provided a structured qualitative analysis of environmental, social, and economic indicators for the countries and industries dormakaba is involved in throughout the value chain.

dormakaba value chain

The basis for the long list of 27 topics incorporate into the assessment were:

- the material and non-material topics under consideration in the 2017/18 materiality assessment, updated based on recent risk assessments and due diligence processes (particularly on human rights);

- circular economy, as an additional topic based on the sustainability context of the industries in our value chain; and

- the topic of Responsible Tax Practices.

Overall, the assessment process has not only helped to identify hotspots along the value chain, it has also generated internal momentum and deepened the understanding of these impacts. It serves as a basis for informed decision-making as the company manages its sustainability efforts going forward.

Stakeholder dialogue for materiality

The second dimension in the materiality assessment focused on the relevance of sustainability topics for our stakeholders, both internal and external. The stakeholder dialogue was thorough and validated in a robust, multi-stage process. This included an online survey of over 2,000 employees around the world, around 100 senior managers, including members of the Executive Committee, and a separate survey for the members of the Sustainability Working Group and other employees who regularly deal with sustainability matters in their day-to-day work. Additionally, bilateral discussions with members of the Group Sustainability Council and external representatives such as investors, banks, customers, suppliers, partners, and local government were conducted.

Reporting Frameworks

This report has been prepared in accordance with the GRI Standards.

dormakaba also reports to the Carbon Disclosure Project annually. This financial year, dormakaba achieved a B score for the report.

dormakaba is a member of the UN Global Compact and publishes an annual Communication on Progress on the UN Global Compact website.

Threshold-setting and validation

The results of the impact assessment and stakeholder dialogue were quantified in the dormakaba Materiality Matrix. A recommendation to the Group Sustainability Council on the proposed threshold for material topics was developed in a workshop with the Sustainability Working Group. Stakeholders included representatives from a range of global and regional functions within the Procurement, Human Resources, Compliance, Operations, EHS, and Product Development departments.

The majority of topics where dormakaba was shown to have a medium to high impact on sustainable development were taken up as material. These were topics where dormakaba either makes a positive contribution to sustainable development – for example through job creation or training – or topics whereby our own operations or those of business partners and suppliers could have a negative impact, for example energy consumption and greenhouse gas emissions resulting from the manufacturing process. Most topics with a medium to high relevance to our stakeholders were defined as material as well.

In a final step, the proposed material topics were discussed with the Group Sustainability Council and the Executive Committee, which then approved them. In addition, the Executive Committee defined the topic of Diversity as material due to its business relevance (double materiality).

Changes in material topics

Many topics that had been previously defined as material were reconfirmed through the assessment process in FY 20/21. In addition, two new topics were added as material, as seen in the table below. Some topics that had been previously defined as material were shown to be less relevant to stakeholders or the company was deemed to have a reduced potential impact on sustainable development. While these topics are less material within the sustainability framework and targets, we have elected to continue reporting key performance indicators on the topics of anti-corruption, water, and waste in our ESG Performance table. Our commitment to the principles related to anti-corruption continues as we are a member of the UN Global Compact.

|

New material topics |

|

Previously defined as material |

|

Circular Economy |

|

Anti-competitive Behavior |

|

Diversity |

|

Anti-corruption |

|

|

|

Freedom of Association & Collective Bargaining |

|

|

|

Water |

|

|

|

Waste |

dormakaba interactive Materiality Matrix 2021–2027

The dormakaba Materiality Matrix below highlights the material topics we have set strategic targets for, and will monitor and report on through to 2027, while tracking any emerging global issues or risks for future consideration. For each topic, the topic boundaries are defined based on the potential impacts along the dormakaba value chain and prioritized accordingly. Click on each material topic to learn more.

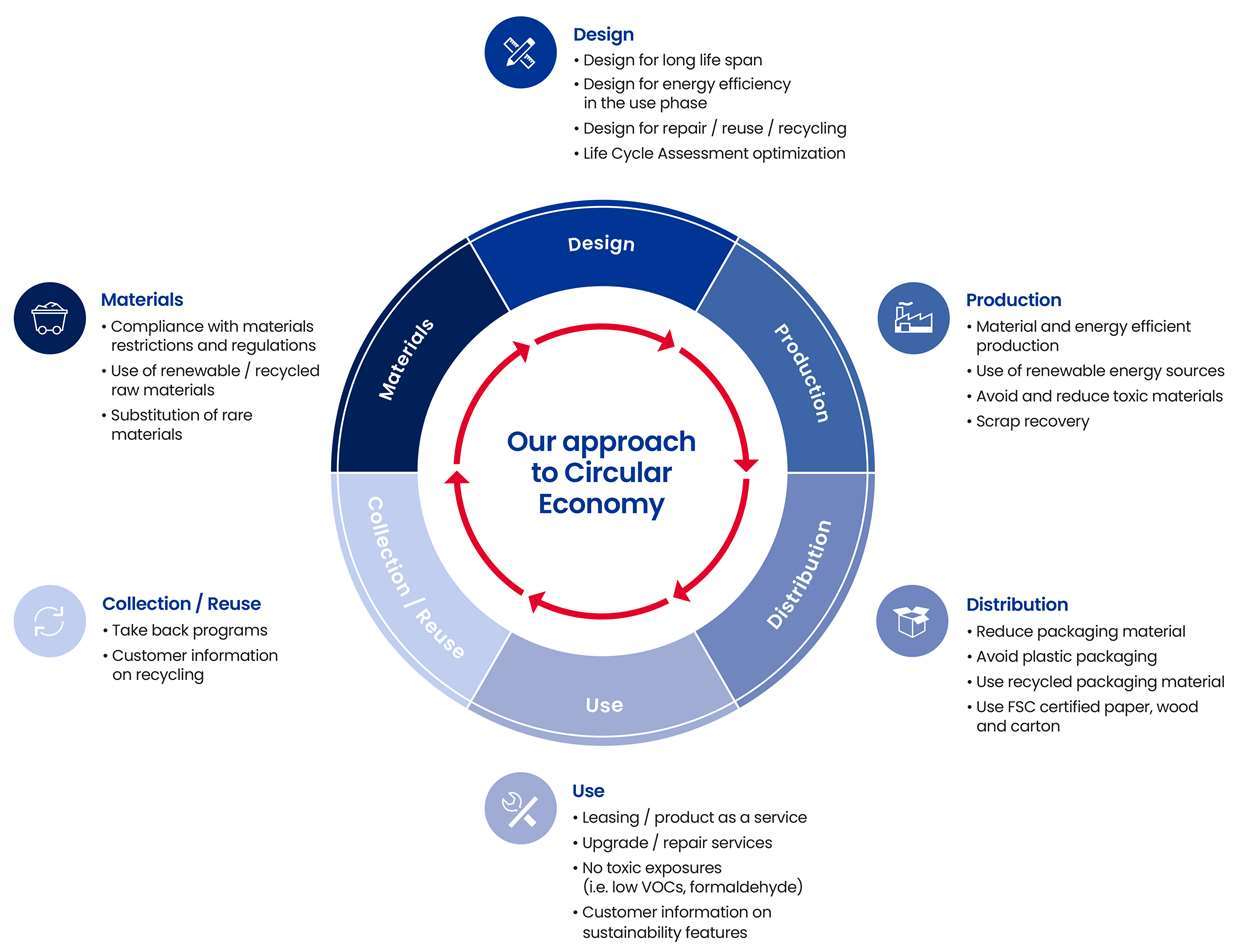

Circular economy

Definition: enhancement of a circular economy approach in operations and product design, e.g., improvement of recyclability, retrofitability, and reparability of products; modular design with reusable and/or replaceable parts; take-back and repair programs; development of product leasing models as an alternative to common buying models; improvement of material efficiency; use of recyclable, biologically degradable, or bio-based plastics and packaging; increased amount of recycled goods purchased.

Potential Impact per Value Chain Step

Customer Health and Safety

Definition: assurance of the health and safety of customers, consumers, and other users.

Potential Impact per Value Chain Step

Diversity

Definition: enhancement of diversity, equal opportunity, and prevention of discrimination along the value chain, e.g., women in leadership positions; integration of people with disabilities, different cultural backgrounds, and nationalities; adaptation to an aging workforce; equal pay; proactive diversity management; prevention of harassment and discrimination on any grounds such as gender, sexual orientation, age, ethnic origin, race, culture, religion, political opinion, or social origin.

Potential Impact per Value Chain Step

Emissions

Definition: greenhouse gas (GHG) emissions and air pollutants in the supply chain, logistics, and operations, e.g., CO2, NOx, SOx, volatile organic compounds (VOCs), fine dust emissions, ozone-depleting substances; reduction of the risk to human health.

Potential Impact per Value Chain Step

Employment

Definition: employment and job creation by the organization and along the value chain, e.g., employment practices, wages, working conditions, hiring and retention of employees, social dialogue, employee-management relations.

Potential Impact per Value Chain Step

Energy

Definition: energy consumption and use of renewable energy in the supply chain, logistics, operations, and products, e.g., energy efficiency, use of local and renewable energy, energy efficiency of products.

Potential Impact per Value Chain Step

Environmental Compliance

Definition: compliance with environmental laws and regulations along the value chain, e.g., reduction of financial risks through fines and negative impacts on reputation, avoidance of clean-up obligations, or other costly environmental liabilities.

Potential Impact per Value Chain Step

Human Rights

Definition: respecting human rights along the value chain, e.g. obligation and training of employees and business partners to adhere to human rights, provision of grievance mechanisms, human rights due diligence. Human rights include but are not limited to freedom of religion, the right to life, protection from discrimination, freedom from slavery and forced labor.

Potential Impact per Value Chain Step

Materials

Definition: efficient use of materials in production and in the supply chain, e.g., optimization of the production process, responsible sourcing of conflict minerals, and wood, ensuring material traceability, responsible use, recycling, and reuse of materials and product recovery, responsible use of scarce materials.

Potential Impact per Value Chain Step

Occupational Health and Safety

Definition: accidents, injuries, and well-being of people involved in activities along the value chain, e.g., workersʼ exposure to risks and hazardous substances, (personal) protective equipment, health and safety training, health checks, case management, ergonomic workspaces.

Potential Impact per Value Chain Step

Supplier Sustainable Development

Definition: reduction of negative environmental and social impacts in the supply chain and of business partners, e.g., supplier screening, due diligence processes, prevention, mitigation, and remediation of negative impacts. Requirement of social standards for suppliers and business partners, e.g., code of conduct, certifications, audits in the supply chain. Sustainable sourcing of raw materials, e.g., impacts of extraction (including conflict minerals), procurement from politically unstable regions.

Potential Impact per Value Chain Step

Training and Education

Definition: enhancement of employee and talent development along the value chain, e.g., vocational training, development planning, performance evaluation, promotion of skills, employee training and education, promotion of lifelong learning opportunities, facilitation of continued employability.

Potential Impact per Value Chain Step

Contact

dormakaba Holding AG

Hofwiesenstrasse 24

8153 Rümlang, Switzerland

Imprint

Project support: Serena Alonso, Ann Fiona Blau, Nicole Claase, Dora Healey, Kristin Jarrett, Lea Rammelmann, Anita Sequeira, Christina Siemsen, Karola Steputat, Malin Fabienne Zühlke

Project management: Stephanie Ossenbach, Marita Burgard, Renata Jendrolovits, Sandi Ruiz

Data quality assurance: Schnabl + Partners, AG

Editor: dormakaba Holding AG

www.dormakabagroup.com

Design: NeidhartSchön, Zurich

Copyright: © dormakaba Holding AG, 2024

Introduction

Three years after launching our sustainability framework and 30+ ESG targets, weʼre proud to share our achievements and future plans. Our goal is to offer more sustainable access solutions for every place that matters.

2023/24 in brief

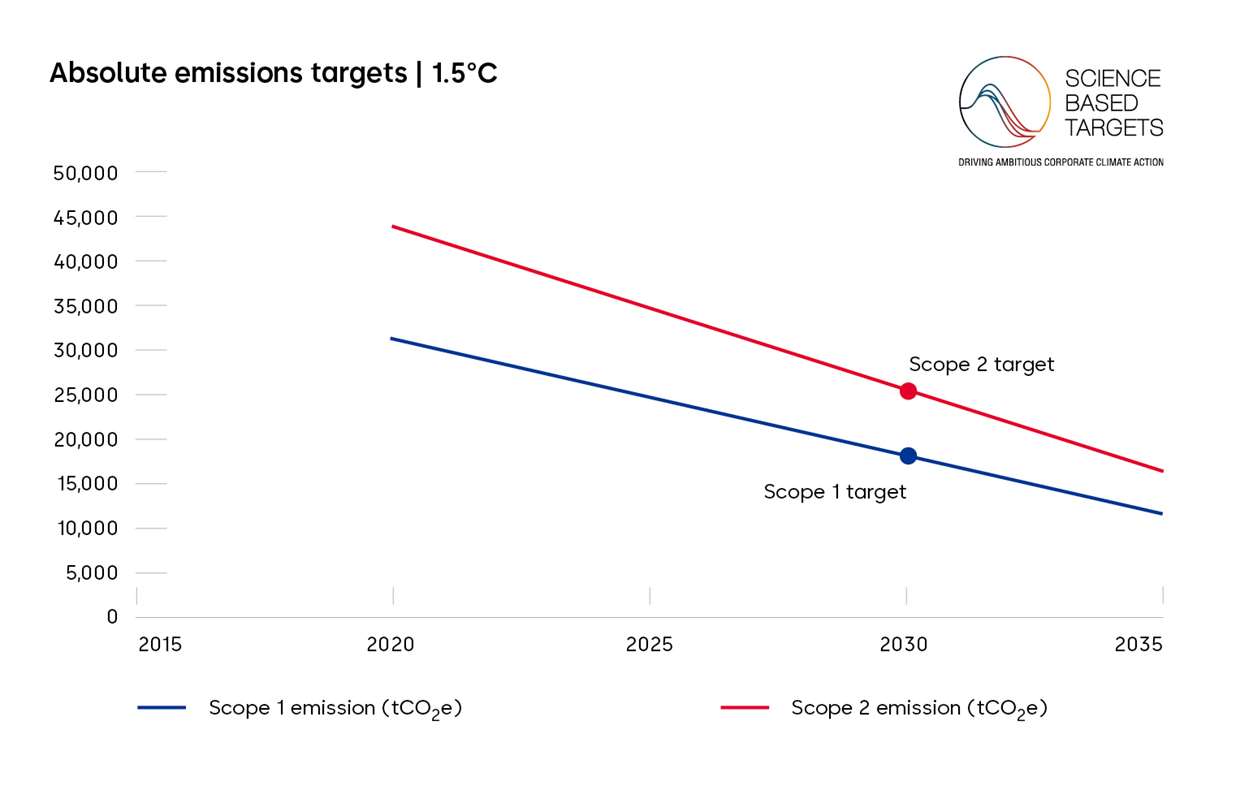

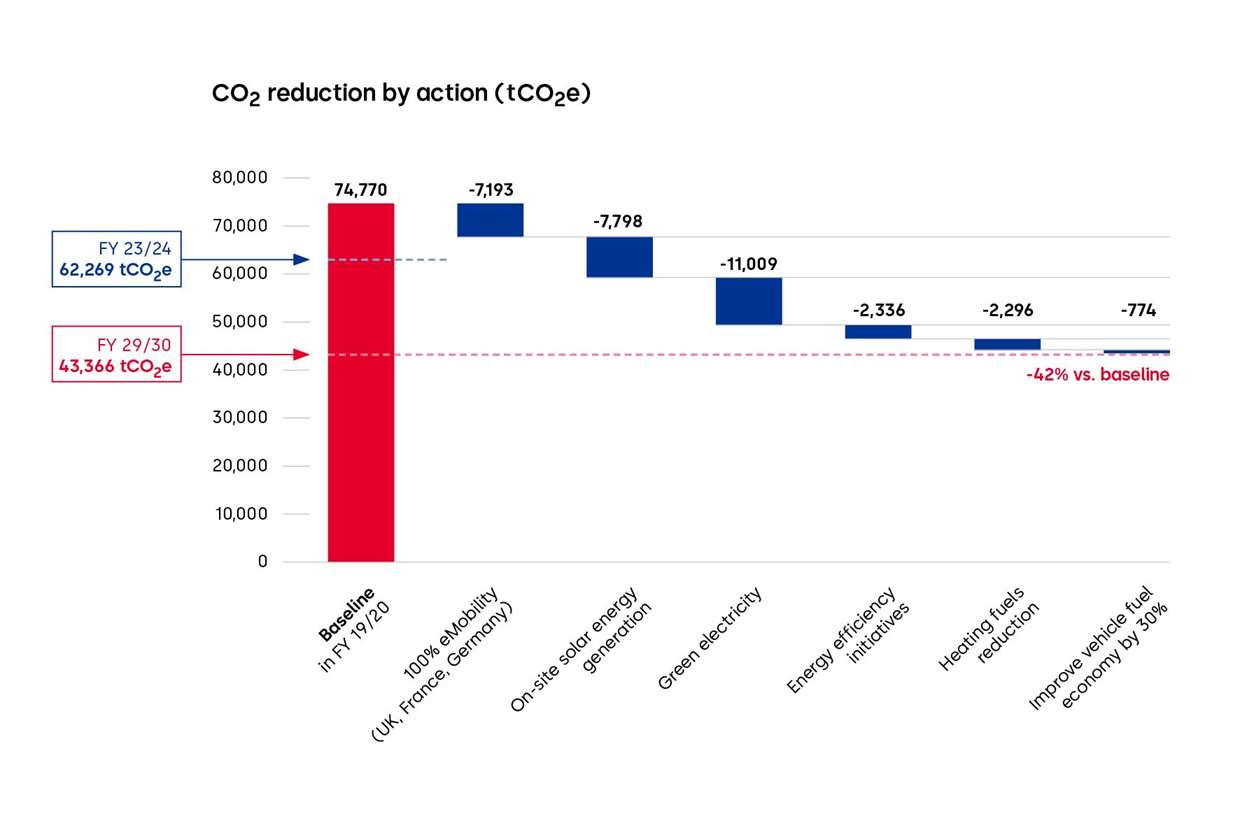

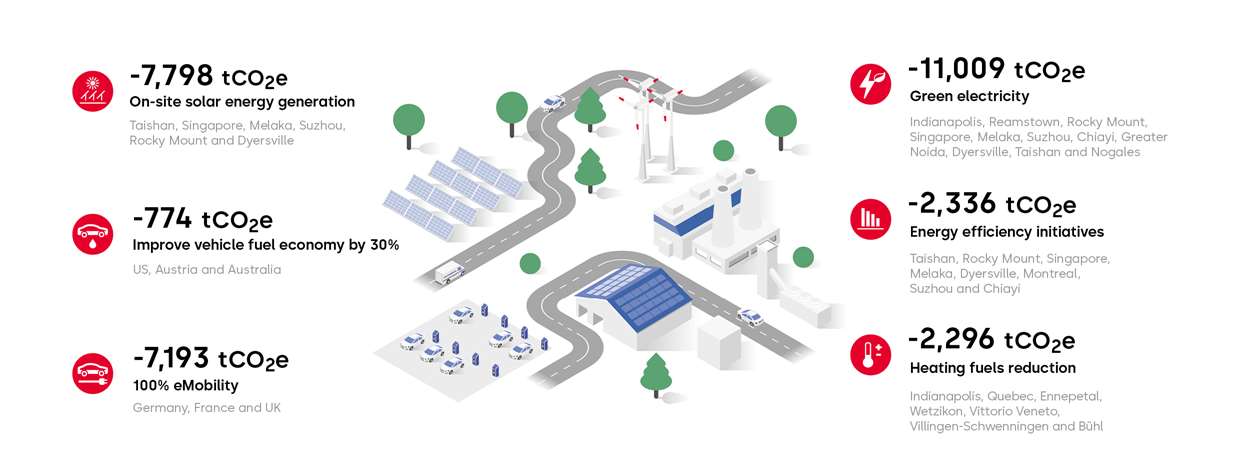

- Scope 1+2 emissions were reduced by 12,500 tCO2e against our baseline in FY 19/20

- We have expanded the production of on-site solar energy by 550% within a year

- The recordable injury rate dropped by 21% against the previous year

- 322 sustainability-related product declarations and certifications are now available

- 164 high-risk suppliers were assessed through our Supplier Sustainability Engagement Program

- 28% of candidates for succession of senior management positions are women

- Commitment to invest nearly CHF 1 million in our child labor remediation project in the Democratic Republic of Congo with Save the Children Switzerland over ten years

- External acknowledgments: Gold medal from EcoVadis; World’s Most Sustainable Companies 2024 by TIME magazine; Europe’s Climate Leaders by the Financial Times; AA rating from MSCI; Prime Status in the ISS-ESG Corporate Rating.

Letter from the CEO

Dear Stakeholders,

Since becoming CEO, I have met many colleagues who support and are excited about our vision of sustainability. And this vision is backed by concrete, quantifiable initiatives on the ground that are making our aspirations a reality — we are letting our actions do the talking.

Looking back on our sustainability achievements during the past financial year, I am proud to highlight some of our key recognitions: we received a gold medal from EcoVadis, were listed as one of the World’s Most Sustainable Companies 2024 by TIME magazine, and have been lauded as one of Europe’s Climate Leaders by the Financial Times. Not only that, we also retained our Prime Status issued by the ISS-ESG Corporate Rating and our AA rating from MSCI. These are all fantastic achievements.

During FY 23/24 we continued our work to reduce our carbon emissions. A prime example of this is the installation and commissioning of three photovoltaic power plants with a total of 21,000 solar panels on the roofs of our production sites in Melaka (Malaysia), Suzhou (China), and Taishan (China). With these, we are now generating 5.5 times more solar energy on site than in the last financial year. Harnessing energy from on-site solar panels is part of our climate transition plan, whose overarching goal is to reduce our operational emissions by 42% by 2030. Since our baseline in FY 19/20, our Scope 1+2 emissions have fallen by 12,500 tCO2e.

At dormakaba, we bring together innovation, customer satisfaction, and sustainability by offering solutions that help our clients meet their own sustainability goals. One of the key tools that has been instrumental in demonstrating our commitment to these values is the dormakaba Door Efficiency Calculator (DEC). By offering a detailed analysis of the impact of our access solutions on a buildingʼs airflow, energy usage, and CO2 emissions, as well as the estimated lifetime costs, our DEC gives our customers a clear picture of the long-term benefits and savings that come from choosing our products. In FY 23/24, we rolled out the DEC in 18 countries and trained over 250 sales colleagues on how best to consult prospective customers.

We have also strengthened our focus on human rights issues both within and outside our operations. Internally, we have set up a Human Rights Risk Management System that covers and classifies all dormakaba locations into four risk categories. This system serves as a basis for prioritizing sites for additional due diligence measures, such as on-site auditing cycles, mandatory training tailored to identified risks, and one-to-one support.

As the CEO of a manufacturing company, I place great importance on the safety and well-being of all my colleagues. This is also a human right. Thanks to our proactive safety culture, we have managed to decrease our recordable injury rate by 21% compared to the previous financial year baseline (1.5 in FY 22/23). This is partly the result of our increased efforts to raise awareness regarding health and safety and partly the simple process involved in reporting unsafe situations. Each unsafe observation that is flagged by our employees is another potential injury avoided. Still, there is another element that has led to greater success in reducing workplace injuries: our Health & Safety Directive. As of FY 23/24, over 77% of our sites have completed an applicability assessment pertaining to the Health & Safety Directive, and over 65% have developed site-specific action plans to eliminate any gaps related to the Directive’s requirements.

To also respect human rights in the supply chain, we have entered into a long-term partnership with Save the Children Switzerland and the Centre for Child Rights and Business as part of a landmark project to remediate child labor victims in small-scale mining communities in the Democratic Republic of Congo (DRC). Over a period of ten years, dormakaba will invest around CHF 1 million in total to support the project’s objectives. We, like any company that sources electronic components, cannot be sure that the cobalt used to manufacture such components does not come from the DRC. We are therefore calling on other companies to join our remediation efforts to collectively address the pervasive issue of child labor in small-scale mining communities in the DRC.

We continue to harness the latest technology in our efforts related to supply chain transparency. In the past year, we introduced a robotic process automation tool named EVA to streamline and accelerate communication processes with thousands of our suppliers with regard to sustainability assessments. In addition, we began using an AI-based risk management tool to close gaps and find, understand, and categorize risks, including sustainability risks, that affect our supply chain. Such tools also enable us to remain compliant with rapidly changing laws and regulations in this field. So far, we have assessed 31.7% of suppliers in our target group.

Finally, like many other publicly listed companies, we are subject to ever-increasing demands from regulators when it comes to environmental and social management. Since 2011, more than 1,200 ESG policy interventions have been introduced worldwide, each one raising the bar as to how a just and sustainable business should act. At dormakaba, we benefit from already having a strong sustainability governance and management foundation, with clear targets and ambitions to guide us.

Even so, the rising tide of new regulations means we have more work to do. This is why we are expanding elements of our sustainability governance and efforts. For example, we have delegated more responsibility to the Board of Directors and the Executive Committee regarding oversight and decisions related to our sustainability targets and measures. Furthermore, this financial year is the first in which we are publishing our TCFD (Task Force on Climate-Related Financial Disclosures) along with our extended EU Taxonomy reports. In addition, we are now reporting according to the requirements of the Swiss Code of Obligations with regard to non-financial reporting. Whatʼs more, to ensure we are in line with the EU Corporate Sustainability Reporting Directive – which will apply to parts of our company from the next financial year – we have completed the required double materiality assessment together with top management and other relevant stakeholders.

As CEO, I encourage my colleagues worldwide to keep supporting our sustainability endeavors in the areas where they have the most impact. This will help us to achieve our global targets, which were set by putting our customers’ needs at the forefront of everything we do. As well as striving to offer them sustainable solutions, we want our customers to be confident in the fact that we manufacture our products in a socially and environmentally responsible manner. Thank you to everyone that has contributed to these goals in the last financial year – keep it up!

Yours sincerely,

Till Reuter

CEO of dormakaba

About dormakaba

Our business

The dormakaba Group (dormakaba) is a leading provider in the access solutions market. The company offers customers a broad, innovative portfolio of products, solutions, and services that easily fit into building ecosystems. With clear portfolio segmentation, dormakaba focuses on its global core businesses Access Automation Solutions (door operators, sliding doors, and revolving doors), Access Control Solutions (connected devices and engineered solutions), Access Hardware Solutions (door closers, exit devices, and mechanical key systems), and Services. The company is also a market leader for Key Systems (key blanks, key cutting machines, and automotive solutions such as transponder keys and programmers) and Movable Walls, which includes acoustic movable partitions and horizontal and vertical partitioning systems.

dormakaba has a long tradition of innovation and engineering expertise. It strives to be an innovation leader that anticipates and fulfills customer needs through continuous technological advancement, creating state-of-the-art solutions that add value for customers and end users alike.

dormakaba is active in around 130 countries and is present in all relevant markets through production sites, distribution and service offices, and collaboration with local partners.

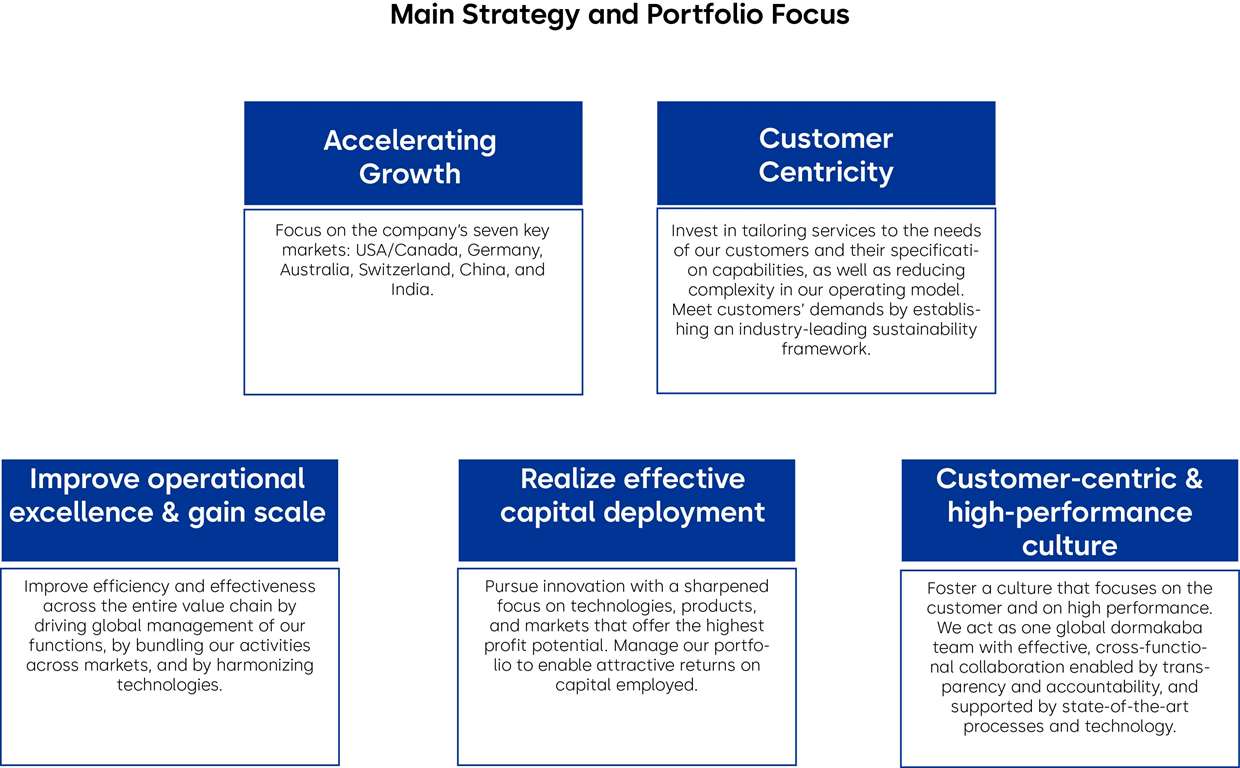

dormakabaʼs corporate strategy – Shape4Growth (S4G) – is about transforming the company, shaping it to its full potential, and accelerating profitable growth. It does so by building on five strategic pillars: Accelerating profitable growth; Focus on customer centricity; Improve operational excellence and gain scale; Realize effective capital deployment; Customer-centric and high-performance culture. Sustainability is a key focus of our customer centricity pillar.

Click here for more information about the strategy.

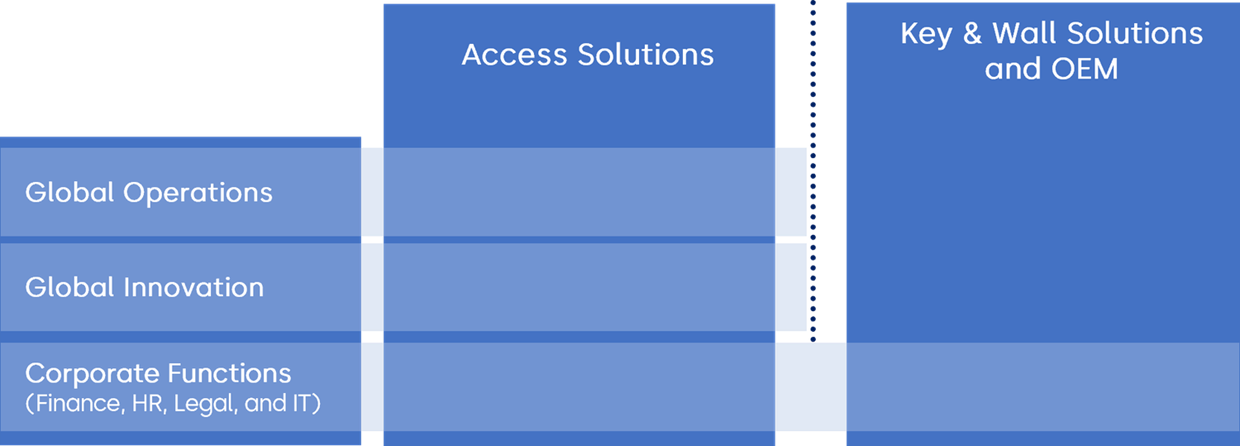

Operating model

Under the Shape4Growth strategy, dormakaba’s operating model builds on globalized management of our Operations and Product Development (Innovation) functions to secure efficiencies of scale and business synergies. This setup extends to globally managed Finance and HR functions.

Since 1 July 2023, the Executive Committee has comprised the CEO, CFO, Chief Operations Officer (COO), Chief Commercial Officer (CCO), and Chief Innovation Officer (CIO), along with the President Key & Wall Solutions and OEM.

The CCO leads all Access Solutions market organizations, with those in our “5+2” key markets reporting directly and the others managed through three country clusters for increased efficiency. Customer excellence functions such as Strategic Marketing, Global Accounts & OEM, Services, and Product Management for Access Hardware Solutions and Access Automation Solutions are also under the CCO’s leadership.

Product Development, along with the combined Access Control Solutions and EntriWorX product management organization, are the responsibility of the CIO. The distinction reflects the different requirements of mature versus emerging businesses: it allows management of more mature product segments in Access Hardware Solutions and Access Automation Solutions to move closer to the market, enabling faster innovation in newer and more dynamic segments. Product Development encompasses three main competence center areas: Software, Hard/Firmware, and Mechanical Engineering. In addition to these competence centers, the Global Architecture team plays a crucial role in defining the technology standards, ensuring consistency and excellence across all products. Engineering Management oversees the planning and execution control of all development programs, ensuring that strategic objectives are met.

A detailed description of the structure can be found in the Notes to the consolidated financial statements for financial year 2023/24.

Our value chain

Our employees1

Employees by region

Employees by contract type

Employees by employment type

The key performance indicators for the above human resources data and the fluctuation figures available in the Fair Employment chapter and the ESG Performance Table are based on 100% of dormakaba Group employees as at 30 June 2024. The total workforce in this scope consisted of 15,736 employees, based on headcount. While the majority of our employees work full-time and on the basis of permanent contracts, 6% are engaged on a part-time basis. 39% of the employees in this scope are covered by collective bargaining agreements. In addition, dormakaba engaged 359 apprentices, trainees, and interns, and employed 2,025 contract workers at the sites in scope.

The collective bargaining coverage and training hours KPIs reported in the Training & Education chapter are based on the scope of employees located at the 111 sites in the reporting coverage as at 30 June 2024 (see Outro, 95% of dormakaba employees).

Product transparency

322

sustainability-related product declarations/ certifications are available

More

Supplier due diligence

164

high-risk suppliers were assessed in our Supplier Sustainability Engagement Program

More

Child labor remediation in the DRC

~CHF1 mio

financial support across ten years for child labor remediation with Save the Children Switzerland

More

Circular Economy & Materials

We are accelerating circular solutions to develop material-efficient, energy-efficient, high-quality products that reduce our customers’ environmental impact and meet the needs of a sustainable built environment.

Our approach

We live in and depend on an interconnected world, with complex environmental, social, economic, and cultural systems. Damaging one element may have an unexpected impact elsewhere. We recognize the limits of our planet and that we must act more sustainably in order to meet increasing social and economic demands. As a leading manufacturer, dormakaba is committed to incorporating the latest product life cycle approaches and environmental technologies to continuously advance our product development and improve our own and our customers’ sustainability performance. This not only provides new opportunities for our design and manufacturing processes; it also addresses our customers’ expectations regarding environmentally friendly products.

We are aware that the sustainability of our products is essential for our success. The Product Sustainability department, under the Global Innovations function, acts as a competence center for all product clusters globally. It provides the right resources, skills, and expertise, and is responsible for shaping a state-of-the-art development environment for product sustainability. This includes, for example, developing Environmental Product Declarations, incorporating sustainability criteria into all product development-related processes, and elaborating guidelines.

Our global Environment Directive regulates minimum business standards on environmental management in manufacturing practices. It also regulates mandatory requirements on product circularity and eco design, including minimum energy efficiency and recycled content benchmarks for each product class. These have also been integrated into our global product development process.

The dormakaba sustainability commitment and life cycle approach are also integrated into our Product Design Manual.

Our activities

Product design with the circular approach

With an average lifespan of 40 to 50 years, buildings should ideally be constructed in a way that allows the required materials and natural resources to be used efficiently. We are dedicated to producing high-quality and reliable products and solutions, while also integrating our customers’ desire for environmentally friendly options. As a result, product design remains a core focus of our sustainability strategy, with an emphasis on energy consumption and carbon emissions during the product’s use phase, waste management, and recyclability at its end of life.

During FY 22/23 we achieved our target of covering all new product developments and optimizations using our circularity approach. We achieved this aim by developing an EcoDesign Specification Template, which has been mandatory for all new product developments since FY 23/24. The template is used as a single source of truth for sustainability criteria for every product development-related process within the dormakaba Group. Therefore, its use is mandated and described in our global product development guideline, the Adaptive Innovation Methodology (AIM) Directive. All local product development processes need to adhere to the AIM Directive. The EcoDesign criteria include guidelines on energy use, materials selection, longevity/durability, repairability, adaptability, and disassembly. The template also defines minimum values for the use of recycled content and how to design and select the product packaging. Further guidance and explanations for the implementation of the different EcoDesign criteria are provided in the Environment Directive.

In FY 23/24, we worked together with Key & Wall Solutions teams to include additional requirements based on their unique product portfolios as well.

Environmentally friendly packaging

For the packaging of our products, we mostly use paper, cardboard, wood and plastic. It is our aim to substitute packaging materials with more sustainable alternatives. By 2027 we want to use zero fossil fuel-based plastic in our packaging (baseline 223 tons in FY 20/21). We also aim to obtain 100% of the paper, wood, and carton from sources that are Forest Stewardship Council (FSC)-certified or similarly certified by other accepted responsible forestry schemes.

We collaborate with our suppliers to highlight the need for them to become certified under a responsible forestry scheme. In order to support our suppliers, we organize meetings together with FSC representatives to raise awareness and clarify questions related to the certification process.

In addition to FSC, we also accept the following standards for forest-based products: Sustainable Forestry Initiative (SFI), American Tree Farm System (ATFS), and the Programme for the Endorsement of Forest Certification (PEFC), as these are also accepted by the green building standard LEED (Leadership in Energy and Environmental Design). In FY 23/24, we were able to confirm that about 25% of our total paper, wood, and cardboard purchases are FSC (or similarly) certified.

We have included the above requirements in an updated Corporate Design Packaging Guideline. Additional new requirements include that preference must be given to water-based inks and adhesives and that plastic packaging should be recyclable and biodegradable. If plastic packaging is currently used, it must contain a minimum of 30% recycled plastic material. Plastic materials such as polystyrene, PVC, or fossil fuel-based plastics should be avoided, and fossil fuel-based plastics must be eliminated by the end of FY 26/27. The Corporate Design Packaging Guideline also includes minimum requirements on material declarations, such as how recycling codes should appear on the packaging.

Due to the ever-changing regulatory landscape, we are constantly adding new requirements to our Corporate Design Packaging Guideline to make sure we are compliant with all global and local laws. We welcome regulations that foster the use of environmentally friendly packaging. For example, since 2022, all packaging imported to Italy has had to carry a material declaration and recycling information. Also in 2022, France introduced a regulation to ban aromatic mineral oil hydrocarbons (MOAH) and saturated petroleum hydrocarbons (MOSH) in packaging and printing inks in two steps starting in 2023. A review with our main packaging suppliers from Germany and Asia confirms that we are compliant with the French law.

In 2024 the European Parliament adopted the Packaging and Packaging Waste Regulation (PPWR), which aims to contribute to a circular economy. The regulations touches on topics such as packaging take-back obligations and the reduction of packaging in landfills. Internally, we have already been working to support this latter requirement through our zero waste to landfill initiative in collaboration with Beyondly, which aims to eliminate waste to landfill by optimizing waste segregation and following the waste hierarchy, as well as finding partners that see a value in our residual materials.

Providing transparent information about our products

By providing transparency for our products regarding their sustainability performance, we secure our market position and offer added value to customers seeking green building certifications.

Material compliance

Since early 2021, components imported or sold in the European Union containing with Substances of Very High Concern (SVHCs) in a concentration higher than 0.1% have had to be reported in the SCIP Database created by the European Chemicals Agency. To be compliant with European regulations, we are continually uploading the required data on SVHCs to the SCIP Database. Furthermore, we adhere to the requirements of the RoHS Directive 2011/65/EU, which restricts the use of certain hazardous substances in electrical and electronic equipment.

In addition to adhering to the EU RoHS and REACH regulations and the Waste Framework Directive, we comply with California Proposition 65, TSCA (Toxic Substances Control Act of 1976), and PFAS regulations for products imported into and/or sold in the USA. The California Proposition 65 requires businesses to provide warnings to Californians about significant exposures to specified chemicals that cause cancer, birth defects, or other reproductive harm. The TSCA addresses the production, importation, use, and disposal of specific chemicals.

PFAS (Per- and Polyfluorinated Substances) chemicals are increasingly regulated due to their link to harmful health effects in humans and animals. Whereas the EU just started the process to further regulate the use of PFAS, several states in the USA have already enacted regulations restricting the use of PFAS in products sold in their markets, and increased restrictions and reporting are on the horizon.

Product declarations and green building certifications

We quantify and disclose a product’s environmental impact across its entire life cycle in our Environmental Product Declarations (EPDs), which are based on the international standards ISO 14025, 14040, and 14044. Our EPDs meet all mentioned standards to ensure that our environmental information is transparent, reliable, and credible.

dormakaba also offers various health-related product declarations, which transparently account for the materials found in our products. These take the form of Health Product Declarations (HPDs) or Building Product Declarations (BPDs), depending on local market requirements.

By 2027, we aim to double our sustainability-related product declarations/certifications, including Cradle to Cradle and for recycled content (baseline 170 in FY 20/21). We currently provide our customers with 322 such declarations and certifications, and we are well on track to meet this target.

Our product declarations are based on Life Cycle Assessments (LCA), which provide a reliable calculation of the environmental performance of a product. This includes the systematic assessment of the environmental impacts arising during the extraction of raw materials and all the way through the production, distribution, use, and end of life phases, which are quantified based on materials, energy consumption, transport routes, emissions, across the life span of the products.

There are two LCA approaches: cradle-to-gate and cradle-to-grave. The first approach considers all production stage modules: raw material supply, transport, and manufacturing. The latter covers all life cycle modules, which means that in addition to the cradle-to-gate stages, cradle-to-grave analyzes the building construction process, the product use stage, and end of life (i.e., the upstream value chain). We mainly use cradle-to-gate “with options” so that we can select the relevant upstream life cycle module(s).

Product information from environmental or health-related product declarations can help our customers attain the highest green building certifications, such as Leadership in Energy and Environmental Design (LEED). dormakaba publishes the product information on internationally recognized sustainability platforms such as the Sustainable Product Information Module (SuPIM) by the Institut Bauen und Umwelt (IBU, Institute for Construction and Environment). SuPIM provides all product-related sustainability data from the manufacturers for various building certification systems such as LEED, the German Sustainable Building Council (DGNB),”Bewertungssystem Nachhaltiges Bauen” (BNB, Evaluation System for Sustainable Construction), and the Building Research Establishment Environmental Assessment Method (BREEAM).

These are compiled in a data sheet and supplemented with the corresponding verification documents. For quality assurance purposes, IBU reviews the data uploaded on their platform. Such platforms provide transparent environmental and health information for users and ensure easy access to specific product data. By providing this level of product information, we seek to lower market entry barriers in the green building industry, enabling our inclusion in related bidding processes.

In FY 23/24, we became members of madaster, a platform that records and documents all materials and products used in buildings and infrastructures to create a comprehensive material database and that promotes a circular economy in the construction industry. Various information about our products is recorded on the platform, for example, material composition, material origin, recyclability and reusability, life cycle data, and information on product certifications and/or declarations. This material database acts as a digital identity card for every building, enabling seamless material traceability and creating a transparent picture of the resource consumption and environmental impact of a building. By no longer viewing buildings as finite resources but as sources of reusable or recyclable materials, we can significantly contribute to climate protection and the conservation of our natural resources.

Activities and key results regarding carbon emissions (Scope 1 & 2) and energy consumption during production.

Production with lower environmental impact

At dormakaba, we recognize that environmental responsibility is integral to producing world-class products. Besides adhering to environmental laws and regulations, we focus on improving our management of environmentally relevant processes and on monitoring and reducing our energy consumption, carbon emissions, water consumption, and effluents, as well as monitoring our waste disposal and recycling rates.

Responsible use of materials

Among the raw materials we use for our products, there are metals such as steel, brass, aluminum, nickel silver, and zinc, as well as gypsum board, glass, and plastics. Other important materials are wood, paper, and cardboard, which are made from renewable resources.

Since the primary extraction of metals from ore and the subsequent refining processes are resource-intensive, one key focus is to increase the use of metals with a high level of recycled content. As mentioned, our Environment Directive sets a minimum amount of recycled content for each material, including these metals. We also work with suppliers to help us obtain certifications on the recycled content of our products. In FY 23/24 we received 23 new recycled content certifications, issued by GreenCircle Certified, for all door closers manufactured in Singapore. This is in addition to the 16 certifications we have for door hardware manufactured in the USA.

Material use (in %)

Raw material use (in %)

Closed-loop processes

Several production sites focus on closed-loop systems in their material use. Manufacturing facilities recycle most internal scrap metal, either by reintroducing the material in their own processes or by selling it to a local recycler. Scrap material is also sent back to the original supplier, who then uses it to make our purchased materials, resulting in a closed-loop system. As an example, our manufacturing plant in Nogales (Mexico) is working on an initiative to return non-recyclable packaging to a vendor for reuse. Analysis of the amount of packaging to be sent back, setting up the collection points at the plant, and defining inspection and shipping processes are being carried out. Additionally, the facility is also separating scrap metal according to alloy. This methodology ensures a more efficient recycling process, and at the same time increases the purchase value paid by our recycling companies.

Waste management

We respect the universal human right to safe and clean drinking water and sanitation. Learn about our activities and key results regarding water and effluents management.

In addition to water consumption and effluents, waste management is of key importance during the electroplating, surface finishing, and painting processes. We work to minimize the volume and toxicity of waste from these operations through continuous improvement projects. Our filter systems ensure that potentially hazardous substances are not released externally. Toxic waste arising from painting and electroplating is disposed of as special waste. Certified disposal companies are commissioned to dispose of industrial waste and chemicals, and to recycle materials.

We monitor our waste by treatment method and waste type. At 73% by weight, the largest proportion of waste is scrap metal. In FY 23/24, approximately 89% of the waste stream was recycled, reused, recovered (including raw materials and energy recovery), or stored on-site.

Non-hazardous waste by type

(in metric tons)

Hazardous waste by type

(in metric tons)

Waste by treatment path

(in metric tons)

Waste intensity

(t/mCHF net sales)

The generation of different waste streams is an inevitable consequence of our operations, although by implementing the circular economy approach, we aim to send zero waste to landfill in our operations by 2027 (baseline 3,443 tons in FY 20/21).

In order to reach our zero waste to landfill goal, 33 manufacturing sites have been tasked with developing road maps for sustainable waste management. Additionally, six sites that account for a combined 67% of our waste to landfill baseline received one-on-one support, including an on-site waste audit and specific waste optimization action plan in collaboration with our external experts from Beyondly. The local management is provided with training, guidance, and advice, and they can share best practices with each other as part of regular meetings.

The zero waste to landfill initiative is aligned with SDG (Sustainable Development Goals) principles by minimizing waste generation and maximizing resource efficiency. The specific action plans include waste stream characterization, segregation to find waste value, diverting key materials from landfill waste, and identifying potential local partners and users of waste streams. Ultimately, this brings economic benefits as well, from cost savings on disposal fees to new revenue streams from recycling.

Local actions to reduce the amount of waste going to landfill were also taken place. Examples in FY 23/24 included:

- In our Chino (USA) plant, we established a policy where throwing out paper waste is banned. Together with an external shredding company, we installed four containers strategically located throughout the facility to increase paper recycling rates. Consequently, landfill waste was reduced by 57% compared to the previous financial year in our Chino plant.

- Our São Paulo (Brazil) site implemented a program for waste recycling and organic waste composting. Our waste is sent to certified recycling plants (paper and plastics), to qualified composting plants (gardening waste), and only a small amount will remain for landfill disposal. In comparison with the previous FY, this location reduced the amount of waste sent to landfill by 82%.

- In Australia, our facility in Hallam has optimized recycling and reduced landfill waste. Individual desk bins were eliminated and instead bulk recycling and waste bins are provided to increase recycling rates. Additionally, hand dryers were installed in rest rooms to eliminate the use of paper towels. Finally, filler packaging materials – such as air-filled plastic pillows and foam – were replaced with perforated cardboard waste. The cardboard waste was derived from incoming materials packaging, thereby finding a good way to reuse what would otherwise have been treated as waste. As a result, landfill waste was reduced by a whopping 75%.

- In Fougères (France), we are extending our storage area for waste recycling bins. For our scheme to implement a successful waste management system, recycling needed to be made as convenient as possible. The waste sent to landfill was reduced by 36% compared to the prior financial year.

- Our team in Singapore is conducting a recycling program to reduce waste in plant operations. This initiative is primarily focused on identifying the waste data sources in order to categorize the recyclable material. This strategy will allow dormakaba Singapore to increase its current recycling rate of 96.2%.

Take-back programs

Most of our products have a long life span of up to 20 years, but their purpose should not end after being uninstalled. Some of the components of our products can be reused, repaired, or reintroduced as raw materials back into the manufacturing cycle.

Collecting products and components from customers and partners requires collaboration between various dormakaba departments. Logistics, quality management, product development, and production are all important functions that should be involved. A take-back program is an extended product responsibility scheme, meaning that whoever introduces a product into a countryʼs market remains responsible for that product after the end of its life. Take-back programs have multiple benefits, such as stronger customer relationships, development of an alternative supply of critical raw materials, mitigated risks associated with hazardous materials handling, reduced environmental impact, and cost savings.

By 2027, we plan to offer extended producer responsibility take-back schemes for all products and packaging in the top ten sales countries.

Closing the loop – solutions for a product take-back program in Germany

In FY 22/23, we accompanied Masterʼs students from the KEDGE Business School’s “Business Transformation Program for Sustainability” program in France in developing a concept for take-back programs for nine countries, focusing on one top-selling product per country. Due to the complexity and the market immaturity for such programs, this financial year we established a strategic partnership with Resourcify, a waste management and recycling expert, to jointly develop product take-back programs in Germany, Switzerland, Austria, and the UK in the current and upcoming financial year.

As a kick-off for the program development with Resourcify, we have organized a workshop in Germany where dormakaba representatives shared their valuable insights from various departments including Product Development, Sales, Quality, and from our European Logistics Center (ELC), where there is already a take-back program in place. New products that are returned by our customers or brought back by our service technicians due to errors in delivery or over-ordering, go through a quality control at the ELC to determine if any of the components or the whole product can be reused.

Furthermore, we invited an important customer, Lindner, to share their experiences with their own product take-back scheme called LinLoop. The program is geared toward the take-back of ceiling and floor tiles and offers flexible return and rental options. At the workshop several great best practices were shared on logistics at construction sites, dealing with recycling firms and refurbishment and remanufacturing processes, and the contractual setup with customers including discount rates, as well as processes to resell these products on the market.

In Germany, door closers were chosen for initial assessment during the workshop, and the potential for reparability, refurbishment, and then recycling was analyzed. The next step for the project team is to analyze similar scenarios for other product groups, such as swing door operators, where there might be more opportunities for reparability and refurbishment due to their electronic chips and components.

Outlook

During the next financial year, we will implement a Product Scoring Model for sustainability, with the aim of assessing the environmental and social performance of our products against five overarching criteria and benchmark data in an objective manner. We will also continue developing sustainability-related product declarations and certifications, with the aim of developing at least 28 new ones, and we will further develop our Door Efficiency Calculator to meet our customers’ needs. Of course, we will continue to pilot product take-back solutions in several markets, including Germany, Switzerland, and the UK.

In terms of Material Compliance, we will implement a compliance and supplier engagement process in Germany to gain more information from our suppliers on hazardous materials and supply chain due diligence for materials in our products.

Another focal point will be to continue developing sustainable packaging concepts – particularly for specific products that are popular in Scandinavia, where the demand for such concepts is very high.

Fair Employment

We strive to create an engaging and fair working environment, where the rights of our employees are respected and where every person can thrive.

Our approach

Our success is based on the engagement and performance of our employees. It is their dedication to delivering excellent solutions to our customers that helps us maintain and further develop our competitive global position. As a company with employees in over 50 countries, we aim to ensure an engaging working environment so that we are an employer of choice for current and prospective employees. We also ensure that we treat employees fairly and in accordance with our company values, and that we provide them with equal opportunities and fair remuneration.

Our approach toward our employees is governed primarily by our Code of Conduct, as well as by country-based labor regulations and the local employee handbooks, where available. Our Group-wide Responsible Labor Directive regulates the minimum business standards during recruitment, hiring, and employment in terms of freely chosen employment, working hours, wages and benefits, the prevention of child labor, freedom of association, and workersʼ accommodation. Furthermore, the Zero Recruitment Fees Directive regulates the business standards regarding fees and costs associated with recruitment governed by the Employer Pays Principle.

Key activities

Engaging our employees

High employee engagement has been proven to lead to increased productivity, fewer workplace accidents, and improved customer satisfaction. A key method for supporting employee engagement is to ensure a culture of open dialogue across the organization.

To monitor any changes in the level of employee engagement, we use a global norm as a benchmark1. Our target is to maintain our Employee Engagement score at or above the Global Norm (currently 73% favorable) until 2027. Our comprehensive global employee survey, the dormakaba dialogue, is sent out every two years, and the last edition in the FY 22/23 saw an employee engagement score of 71%, a slight improvement versus our baseline. Besides this, we initiate smaller Pulse Checks on an annual basis to learn about our employeesʼ engagement level. During the FY 23/24 edition, 6,655 employees worldwide (58% participation rate) gave feedback on the topics of our company strategy and transformation, our Behaviors, the working environment, direct supervisorsʼ relationships, and engagement. The survey was accessible to all employees with a company email address and wherever allowed by local works councils, if existing.

The main findings were:

- Employees are generally satisfied with their direct supervisors (80% favorable answers) and working environment (69% favorable answers). This is a good indicator of a strong management team throughout dormakaba.

- Areas showing the largest room for improvement (50% or less favorable answers) were related to simplifying processes for internal and external customers, feeling part of one global team, and collaboration between departments.

As a follow-up, three workshops were conducted to come up with top-down actions to improve the three least favorably rated survey items. Each workshop focused on one of the above-named topics.

Fair remuneration and benefits

An overview of best practice employment-related benefits and measures across the Group can be found in the Employee Benefits table.

We aim to establish fair compensation that is determined based on job function and relevant local market benchmarks. It is not influenced by personal attributes such as age, nationality, or gender. The global grading system ensures that functions are evaluated in a consistent manner across the organization.

In FY 23/24 we started a global living wage gap assessment to verify that even entry level employees are paid enough to afford the necessities of life based on the local cost of living. We have completed the pilot living wage gap assessment for India and Sweden in the scope of our internal employees, and we will roll out the assessment to all other countries during the next financial year.

Furthermore, following local regulations, 15 entities conducted an audit on equal pay for equal work this financial year. For example, in Switzerland, an independent external auditor verified that the legal entities fully comply with equal pay regulations and there is no statistically significant difference in pay based on gender.

In addition, we provide locally specific benefits and welfare programs. For example, in FY 23/24 we collaborated with a local hospital in Dubai (United Arab Emirates) to offer free breast cancer screening for our female employees over the age of 40 to raise awareness of breast cancer prevention.

Employee attraction and retention

We strive to create a diverse and inclusive workplace, where everyone can be their authentic selves.

We are proud of our diverse workforce, our openness, and our transparency and strive to create an inclusive workplace where everyone can be their authentic selves. All this is part of our company culture. Many factors shape our culture, but the most important one is our behavior: how we work together and how we act toward our customers and colleagues. So that we are clear on what we can expect from each other, we have established six Behaviors that all employees must adopt. We rolled out a Behaviors eLearning course that is available to all employees who have access to the eLearning platform. Additionally, they were incorporated into the performance reviews for employees in selected countries.

By adopting these behaviors, we aim to provide a working environment in which people can thrive and where everybody feels part of one team. We also provide our employees with professional development opportunities to retain our qualified workforce. And when filling open positions, promoting from within our own workforce is preferred.

This financial year we introduced the global Talent Acquisition Directive, which provides a common understanding and key principles for attracting, recruiting, and onboarding talents across the company. The directive includes a clause on Diversity, Equity & Inclusion, aiming to ensure that the attraction, recruitment, and selection practices are free from bias and are fair to candidates, including those with diverse backgrounds. To facilitate the adoption of this directive across our organization, we developed an online training course that is mandatory for all managers and available to all employees with access to our online training platform.

Furthermore, we have successfully built and finalized our global talent acquisition structure and strategy. We now work in global teams, supporting and learning from each other. Our local career websites also follow a global standard, allowing for a consistent candidate experience. And as part of our growth strategy, we have opened dormakaba business services in Sofia (Bulgaria). The new center will serve as a backbone that bundles services and expertise to improve quality, efficiency, and flexibility in HR and other business processes.

Fluctuation

In FY 23/24, a total of 1,930 employees joined the company and 1,801 left within the reporting scope. This corresponds to rates of 13% and 12% respectively, which reflects a slightly higher joiner rate than leaver rate and a lower leaver rate than in the previous year (14%).

Employee fluctuation across all business regions was similar, with higher rates being seen in Australia and New Zealand, where we see higher attrition rates from employees who have been at the company for less than one year. To reverse this trend, an onboarding system is being developed so that our new starters are feel better supported and educated when they start working with us.

Some fluctuation can be attributed to our S4G transformation program. Through this program we aim to simplify processes, become more efficient, reduce costs, and invest the freed-up resources in growth and innovation. While the programʼs implementation may impact up to 1,800 positions, the expected net reduction of full-time equivalent positions will be approximately 800. Of these, as part of the implementation of the various initiatives, approximately 700 full-time positions will be reduced in Austria, Germany, and Switzerland over three financial years until the end of June 2026. Communication about the restructuring process has been transparent through townhall meetings, internal articles, and in-person conversations with the affected employees.

About 400 of the affected positions are in Germany, where intensive negotiations took place between the employee representatives and dormakaba to find socially acceptable solutions for all those affected and to significantly reduce and, if possible, avoid layoffs. Solutions to mitigate the negative economic consequences for the employees affected were agreed in a social plan. For example, we offered early retirement opportunities wherever possible. All employees affected by a layoff were offered a transfer period of five months so that they could qualify for a new job in addition to receiving a severance payment.

In Switzerland, a social agreement was successfully concluded and signed by representatives of the Swiss companies and the Swiss Employee Representation (ANV). The social agreement contains a range of measures to support and safeguard the employees concerned. These include individual job search support as well as advice from external outplacement specialists, compensation for potential salary disadvantages in the event of internal and external reemployment, or extended or shortened notice periods in the employees’ favor.

In Austria, the company and the works council concluded an agreement on measures to prevent, eliminate, or mitigate the consequences of the restructuring. A social plan has been developed for those employees who are affected by the restructuring measures to mitigate the adverse consequences of the changes, for example through severance payments in the event of job loss or relocation support in the event of a job being shifted from one Austrian site to another.

Outlook

In the next fiscal year, we will continue to execute the restructuring program in a socially responsible manner. Beyond that, we will focus on improving and expanding our candidate experience, and build on as well as simplifying our improved global recruitment processes. We will also continue to roll out our global recruitment tool to the remaining 25 countries to harmonize processes. Finally, we will also complete the living wage gap assessment and begin developing actions to close any gaps discovered.

GRI content index

|

Statement of use |

|

dormakaba has reported in accordance with the GRI Standards for the period 1 July 2023 to 30 June 2024. |

|||||

|

GRI 1 used |

|

GRI 1: Foundation 2021 |

|||||

|

Applicable GRI Sector Standard(s) |

|

No GRI Sector Standard is available yet |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GRI STANDARD/ OTHER SOURCE |

|

DISCLOSURE |

|

LOCATION |

|

|

OMISSION |

|

General disclosures |

|

|

|

|

|

||

|

GRI 2: General Disclosures 2021 |

|

2 – 1 Organizational details |

|

SR, Outro, About this report |

https://report.dormakaba.com/2023_24/en/?p=10030#aboutreport |

|

|

|

|

|

AR, Corporate information |

|

|

|||

|

|

|

AR, Business Performance |

|

|

|||

|

|

2 – 2 Entities included in the organization’s sustainability reporting |

|

SR, Outro, Reporting coverage and processes |

|

|

||

|

|

2 – 3 Reporting period, frequency, and contact point |

|

SR, Outro, About this report |

https://report.dormakaba.com/2023_24/en/?p=10030#aboutreport |

|

|

|

|

|

|

SR, Outro, Contact |

|

|

|||

|

|

2 – 4 Restatements of information |

|

SR, Outro, About this report |

https://report.dormakaba.com/2023_24/en/?p=10030#aboutreport |

|

|

|

|

|

2 – 5 External assurance |

|

Assurance Report |

|

|

||

|

|

|

AR, Corporate Governance, Auditors |

|

|

|||

|

|

2 – 6 Activities, value chain, and other business relationships |

|

SR, Introduction, About dormakaba |

|

|

||

|

|

|

SR, Strategy & Approach, Stakeholder dialogue and partnerships |

https://report.dormakaba.com/2023_24/en/?p=10066#stakeholderdialogue |

|

|

||

|

|

|

SR, Outro, Significant changes to the organization and its supply chain |

https://report.dormakaba.com/2023_24/en/?p=10030#significantchanges |

|

|

||

|

|

|

AR, Corporate information |

|

|

|||

|

|

2 – 7 Employees |

|

SR, Introduction, Our employees |

https://report.dormakaba.com/2023_24/en/?p=10105#workforcecomposition |

|

2 – 7.b. Information unavailable/incomplete for regional breakdown. |

|

|

|

|

SR, Fair Employment, Fluctuation |

https://report.dormakaba.com/2023_24/en/?p=10075#fluctuation |

|

|

||

|

|

|

SR, ESG Performance Table |

|

|

|||

|

|

2 – 8 Workers who are not employees |

|

SR, Introduction, Our employees |

https://report.dormakaba.com/2023_24/en/?p=10105#workforcecomposition |

|

|

|

|

|

|

SR, ESG Performance Table |

|

|

|||

|

|

2 – 9 Governance structure and composition |

|

AR, Corporate Governance, Board of Directors (BoD) |

|

|

||

|

|

2 – 10 Nomination and selection of the highest governance body |

|

AR, Corporate Governance, Board of Directors (BoD) |

|

|

||

|

|

2 – 11 Chair of the highest governance body |

|

AR, Corporate Governance, Board of Directors (BoD) |

|

|

||

|

|

2 – 12 Role of the highest governance body in overseeing the management of impacts |

|

AR, Corporate Governance, Board of Directors (BoD) |

https://report.dormakaba.com/2023_24/board-of-directors#responsibilities |

|

|

|

|

|

2 – 13 Delegation of responsibility for managing impacts |

|

SR, Outro |

|

|

||

|

|

|

SR, Strategy & Approach |

https://report.dormakaba.com/2023_24/en/?p=10066#sustanabilityorganization |

|

|

||

|

|

|

AR, Corporate Governance, Board of Directors (BoD) |

https://report.dormakaba.com/2023_24/board-of-directors#responsibilities |

|

|

||

|

|

2 – 14 Role of the highest governance body in sustainability reporting |

|

SR, Outro |

|

|

||

|

|

|

SR, Strategy & Approach |

https://report.dormakaba.com/2023_24/en/?p=10066#sustanabilityorganization |

|

|

||

|

|

2 – 15 Conflicts of interest |

|

AR, Corporate Governance, Group structure and shareholders |

https://report.dormakaba.com/2023_24/group-structure-and-shareholders#shareholders |

|

|

|

|

|

|

AR, Compensation Report, External mandates |

|

|

|||

|

|

2 – 16 Communication of critical concerns |

|

SR, Outro, Transparency and compliance |

|

2 – 16.b. Omitted due to confidentiality constraints. |

||

|

|

2 – 17 Collective knowledge of the highest governance body |

|

SR, Strategy & Approach |

https://report.dormakaba.com/2023_24/en/?p=10066#sustanabilityorganization |

|

|

|

|

|

|

Corporate Governance, BoD members |

https://www.dormakabagroup.com/en/investors/corporate-governance#board-of-directors |

|

|

||

|

|

|

AR, Corporate Governance, Board of Directors (BoD) |

https://report.dormakaba.com/2023_24/board-of-directors#responsibilities |

|

|

||

|

|

2 – 18 Evaluation of the performance of the highest governance body |

|

AR, Compensation Report, Managing compensation |

|

|

||

|

|

|

AR, Compensation Report, Compensation architecture for the EC |

https://report.dormakaba.com/2023_24/architecture-ec#total_target_comp#compensationlti |

|

|

||

|

|

2 – 19 Remuneration policies |

|

AR, Compensation Report, General Introduction |

|

|

||

|

|

|

AR, Compensation Report, Compensation at a glance |

https://report.dormakaba.com/2023_24/compensation-at-a-glance |

|

|

||

|

|

|

AR, Compensation Report, Compensation architecture for the BoD |

|

|

|||

|

|

|

AR, Compensation Report, Compensation architecture for the EC |

|

|

|||

|

|

2 – 20 Process to determine remuneration |

|

AR, Compensation Report, Compensation at a glance |

https://report.dormakaba.com/2023_24/compensation-at-a-glance |

|

|

|

|

|

|

AR, Compensation Report, Basic principles of compensation |

|

|

|||

|

|

|

AR, Compensation Report, Managing compensation |

|

|

|||

|

|

|

AR, Compensation Report, Compensation architecture for the BoD |

|

|

|||

|

|

|

AR, Compensation Report, Compensation architecture for the EC |

|

|

|||

|

|

2 – 21 Annual total compensation ratio |

|

|

|

|

Information unavailable/incomplete. Calculation is not available. |

|

|

|

2 – 22 Statement on sustainable development strategy |

|

UN Global Compact Communication on Progress; CDP Report; Modern Slavery and Child Labor Statement |

|

|

||

|

|

|

dormakaba Statement on Diversity, Equity & Inclusion |

|

|

|||

|

|

2 – 23 Policy commitments |

|

SR, Strategy & Approach |

|

|

||

|

|

|

SR, Human Rights, Our approach |

|

|

|||

|

|

|

SR, Human Rights, Policy commitment |

https://report.dormakaba.com/2023_24/en/?p=9918#policycommitment |

|

|

||

|

|

|

SR, Supplier Sustainable Development, Our approach |

|

|

|||

|

|

|

SR, Circular Economy & Materials, Our approach |

|

|

|||

|

|

|

SR, Occupational Health & Safety, Our approach |

|

|

|||

|

|

|

SR, Fair Employment, Our approach |

|

|

|||

|

|

|

SR, Diversity, Equity & Inclusion, Our approach |

|

|

|||

|

|

2 – 24 Embedding policy commitments |

|

SR, Strategy & Approach |

|

|

||

|

|

|

UN Global Compact Communication on Progress; CDP Report; Modern Slavery and Child Labor Statement |

|

|

|||

|

|

|

Information can be found in all Pillar chapters of this Sustainability Report |

|

|

|

||

|

|

2 – 25 Processes to remediate negative impacts |

|

SR, Human Rights, HRDD |

|

|

||

|

|

|

SR, Outro, Transparency and compliance |

|

|

|||

|

|

|

Whistleblowing system |

https://www.dormakabagroup.com/en/investors/corporate-governance/whistleblowing |

|

|

||

|

|

2 – 26 Mechanisms for seeking advice and raising concerns |

|

SR, Outro, Transparency and compliance |

|

|

||

|

|

|

SR, Human Rights, HRDD |